Great-plains NTA3007HD Predelivery Manual User Manual

Browse online or download User Manual for Gardening equipment Great-plains NTA3007HD Predelivery Manual. Great Plains NTA3007HD Predelivery Manual User Manual

- Page / 70

- Table of contents

- BOOKMARKS

- Manufacturing, Inc 1

- Table of Contents 3

- 166-207M 03/29/2010 4

- Important Safety Information 5

- Use A Safety Chain 6

- Avoid High Pressure Fluids 6

- Tire Safety 6

- Practice Safe Maintenance 7

- Safety At All Times 7

- Introduction 8

- Getting Started 9

- Forklift 9

- Shipment Inventory 10

- Unloading the Racks 11

- 166-207Q 03/29/2010 12

- Bin Rack 13

- 03/29/2010 166-207Q 15

- Cart Rack 18

- Tools Required 33

- Pre-Assembly Checklist 33

- Assembly (General Sequence) 33

- Assembly 34

- Assemble Cart Front Wheels 35

- Assemble Contact Drive Wheels 35

- Adjusting Drive Wheels 35

- Assemble & Install Meters 36

- Meters Face Same Direction 36

- Bin Lids and Silicone Sealant 37

- Bin Lids 37

- Bin Lid Closing 38

- Bin Strainer 38

- Bin Ladder Mounting 39

- Assemble Ladder to Cart Frame 40

- Verify Ladder Function 41

- Assemble Bins to Frame 42

- Bins Mounted 42

- Adjustment) 46

- Assemble Center Towers 47

- Assemble Wing Towers 48

- Wing Tower Placement 48

- Wing Tower Hoses 49

- Seed Hose Port Maps: 49

- Assemble Tongue and Jack 50

- Assemble Pullbars (front) 51

- Assemble Pullbars (back) 51

- Assemble Hitch 52

- Air Drill Hitched to Tractor 52

- Route Hoses 53

- Hydraulic Hose Hookup 54

- Hydraulic Hose Installation 55

- Opener Lift Hydraulics 56

- Wing Fold 56

- Wing Opener Tilt Hydraulics 57

- Wing Tilt 57

- Transport Hook 58

- Wing Movement During Hook 58

- Auger Hydraulics 59

- Auger Latched for Movement 60

- Deploying the Auger 60

- Fan Hydraulics 61

- Fan Mount 61

- Fan/Auger Selector Valve 61

- Weight Transfer Hydraulics 62

- Adjusting Weight Transfer 62

- Electric Harness (Monitor) 63

- Electric (Lights) 63

- Brake Hookup (Option) 64

- Parking Brakes 65

- Air Brakes 66

- Air Brake Connectors 66

- Hydraulic Brakes 67

- International Decals 68

- Salina, Kansas 67402-5060 USA 70

Summary of Contents

Manufacturing, Inc.www.greatplainsmfg.com© Copyright 2010 Printed 03/29/2010 166-207QExport Pre-Delivery InstructionsNTA907HD9m/30ft No-Till Heavy Dut

6 NTA907HD166-207Q 03/29/2010Shipment InventoryThis drill was disassembled and attached to 3 racks fortransporting. Remove all loose accessories (list

Unloading the Racks 703/29/2010 166-207QUnloading the RacksRefer to Figure 8 and Figure 9Opener RackREMOVE RH and LH OPENER SECTIONS (fromeach side

8 NTA907HD166-207Q 03/29/2010Refer to Figure 10Place 4 straps as shown to lift the opener section.Figure 10Strap Placement for Lifting OpenerSections7

Unloading the Racks 903/29/2010 166-207QRefer to Figure 11Bin Rack1. Remove all loose parts inside the bins.These partswill be necessary in the assemb

10 NTA907HD166-207Q 03/29/2010Refer to Figure 13BIN RACK:• 2 Bins• 2 Wing Weldments• 4 Loose WheelsRefer to Figure 144. Remove one bin resting it on f

Unloading the Racks 1103/29/2010 166-207QRefer to Figure 155. Remove 4 loose wheels stored under the bins (sothere is no likelihood of their getting p

12 NTA907HD166-207Q 03/29/2010Refer to Figure 17Two Wing WeldmentsRefer to Figure 187. Remove one wing weldment at a time by first remov-ing the one bo

Unloading the Racks 1303/29/2010 166-207QRefer to Figure 198. Place an overhead strap attached to the forkliftthrough the top hole in one wing weldmen

14 NTA907HD166-207Q 03/29/2010Refer to Figure 22Cart Rack• 1 Cart Main Frame• 1 Auger• 2 Pullbars• 1 Tongue with Hitch• 1 Cart Fan Assembly• 2 Wing Fr

Unloading the Racks 1503/29/2010 166-207QRefer to Figure 24LOOSE PARTS3. Remove all loose parts that you can access.Refer to Figure 254. Remove 4 bin

16 NTA907HD166-207Q 03/29/2010Refer to Figure 26LOOSE PARTS6. Remove later: 2 Meter boxes wrapped in plastic (onbottom of rack underneath all the othe

Unloading the Racks 1703/29/2010 166-207QRefer to Figure 27THE AUGER (Option)7. With tin snips, remove metal banding securingthe auger in the two cra

18 NTA907HD166-207Q 03/29/2010Refer to Figure 29THE FAN9. Remove cart fan from rack.Refer to Figure 3010. The cart fan is secured to the rack with 4

Unloading the Racks 1903/29/2010 166-207QRefer to Figure 31CART MAIN FRAME11. Remove 6 U-bolts located at each side and endsecuring the cart main fra

20 NTA907HD166-207Q 03/29/2010Refer to Figure 3313. Place 2 straps on back of cart to lift cart out of rack.Refer to Figure 3414. Lifting the cart fra

Unloading the Racks 2103/29/2010 166-207QPULLBARSRefer to Figure 3515. Remove metal banding securing the end of thepullbars to the rear end of the t

22 NTA907HD166-207Q 03/29/2010Refer to Figure 3717. Using 2 straps, place one at each end and removeone pullbar.Refer to Figure 3818. Remove 2nd pull

Unloading the Racks 2303/29/2010 166-207QRefer to Figure 39THE TONGUE19. Place 2 forklift straps at each end of tongue (asshown).Refer to Figure 40(St

24 NTA907HD166-207Q 03/29/2010Refer to Figure 4120. Remove 4 U-Bolts securing the rear end oftongue to the rack.Refer to Figure 4221. Remove one bolt

Unloading the Racks 2503/29/2010 166-207QRefer to Figure 4322. Remove tongue from rack.Refer to Figure 4423. Place 2 straps, one at each end of one wi

iii03/29/2010 166-207M© Copyright 2009, 2010. All rights ReservedGreat Plains Manufacturing, Inc. provides this publication “as is” without warranty o

26 NTA907HD166-207Q 03/29/2010Refer to Figure 45THE 2 WING FRAME UNITS24. Remove 2 bolts securing hoses to one wingframe unit.Refer to Figure 4625. R

Unloading the Racks 2703/29/2010 166-207QRefer to Figure 4727. Remove one bolt securing the other end of thewing frame to rack.Refer to Figure 4828.

28 NTA907HD166-207Q 03/29/2010Refer to Figure 4929. Remove 2 meters (wrapped in plastic).Refer to Figure 5030. Unbolt the 2nd wing frame unit repeatin

Assembly Sequence and Preparation 2903/29/2010 166-207QAssembly Sequence and PreparationInstructions for assembling the implement begin in thenext sec

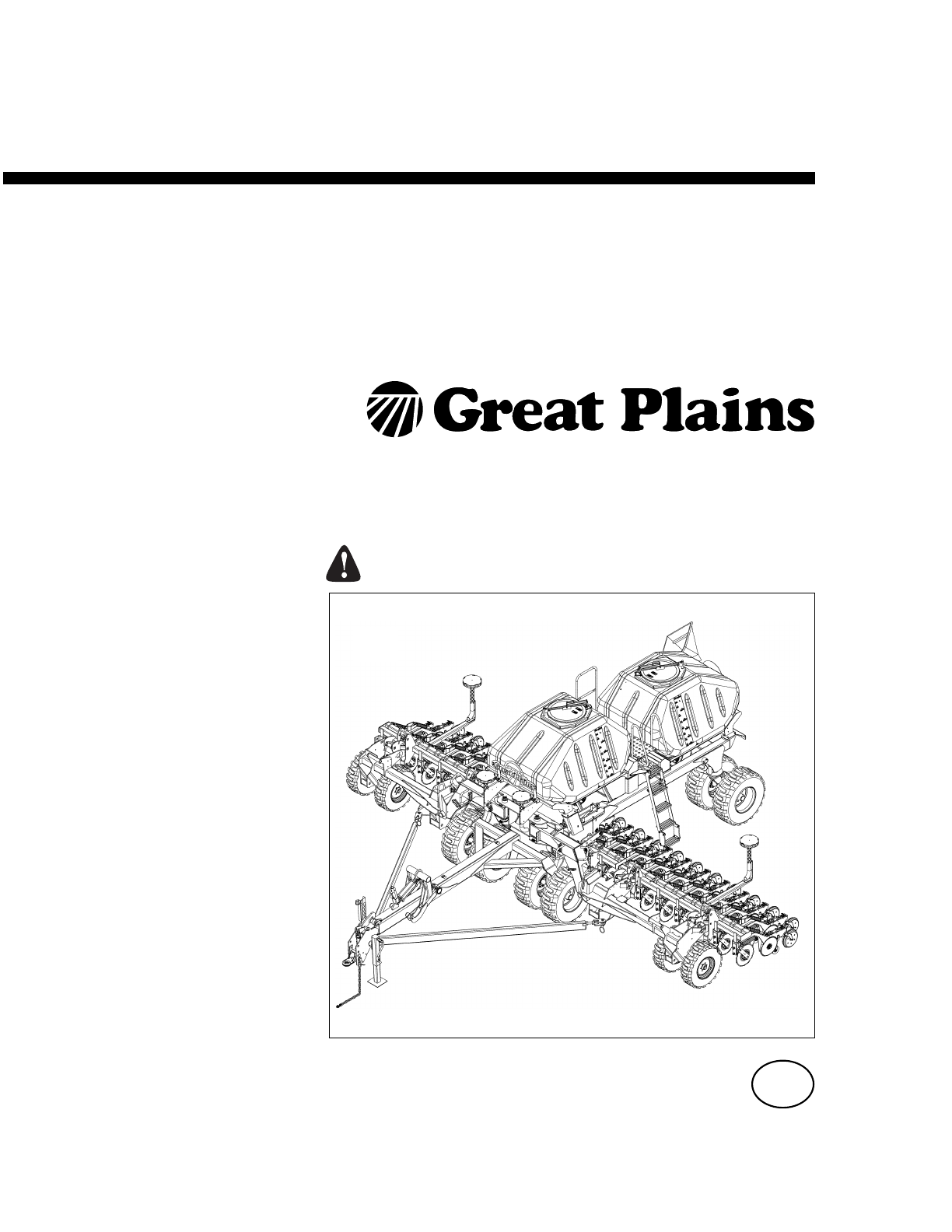

30 NTA907HD166-207Q 03/29/2010AssemblyNTA907HD Fully AssembledRefer to Figure 51LRUDFBLRFigure 51NTA907HD Assembled29423Figure 52NTA907HD0337

Assembly 3103/29/2010 166-207QAssemble Cart Front Wheels(see Parts Manual page: Cart Transport Wheels withoutBrakes. If machine has optional brake equ

32 NTA907HD166-207Q 03/29/2010Assemble & Install Meters(see Parts Manual section: Meter Box Assembly)(see Operator Manual section: Adjustments)Ref

Assembly 3303/29/2010 166-207QBin Lids and Silicone Sealant(see Parts Manual section: Bin Assembly)(see Operator Manual section: Operating Instruction

34 NTA907HD166-207Q 03/29/2010Bin Lid ClosingRefer to Figure 611. Swing lid over opening until capture hook is cen-tered on U-bolt .2. Open handle a

Assembly 3503/29/2010 166-207QAssemble 2 Ladders Inside Bins(see Parts Manual section: Bin Assembly)Refer to Figure 63MAKE SURE:Make sure to install l

166-207M 03/29/2010

36 NTA907HD166-207Q 03/29/2010Assemble Ladder to Cart Frame(see Parts Manual section: Walkboard and Ladder)(see Operator Manual section: Operating Ins

Assembly 3703/29/2010 166-207QVerify Ladder Function(see Parts Manual section: Walkboard and Ladder)(see Operator Manual section: Operating Instructio

38 NTA907HD166-207Q 03/29/2010Assemble Bins to Frame(see Parts Manual section: Bin to Frame)Refer to Figure 68Bins MountedRefer to Figure 69Figure 68A

Assembly 3903/29/2010 166-207QAssemble Center Opener Weldment(see Parts Manual section: Opener Mount to Frame)Refer to Figure 70 and Figure 71Orientat

40 NTA907HD166-207Q 03/29/2010Assemble Folding Wing Weldments(see Parts Manual section: Wing to Frame)Refer to Figure 72Step 1:• Remove wing fold pin

Assembly 4103/29/2010 166-207QRefer to Figure 74Step 3:1. Coat pivot holes in frame with antisieze com-pound.2. Put shim stack (from Step 2) over piv

42 NTA907HD166-207Q 03/29/2010Assemble Opener Mounts to Wing(see Parts Manual section: Opener Mount to Wing)(see Operator Manual section: Opener Sub-F

Assembly 4303/29/2010 166-207QAssemble Center Towers(see Parts Manual section: Tower Assembly)Refer to Figure 77With drill raised (so openers are drop

44 NTA907HD166-207Q 03/29/2010Assemble Wing Towers(see Parts Manual section: Tramline Mounting)Refer to Figure 78To mount tower:1. Dismount opener spr

Assembly 4503/29/2010 166-207QWing Tower HosesRefer to Figure 80With drill raised (so openers are dropped down), hosesshould be as short as possible.S

Important Safety Information 103/29/2010 166-207QImportant Safety InformationLook for Safety SymbolThe SAFETY ALERT SYMBOL indicates there is apotenti

46 NTA907HD166-207Q 03/29/2010Assemble Tongue and Jack(see Parts Manual section: Tongue to Frame)Refer to Figure 81TongueJackParking(see Operator Manu

Assembly 4703/29/2010 166-207QAssemble Pullbars (front)(see Parts Manual section: Hitch)Refer to Figure 83Assemble Pullbars (back)(see Parts Manual se

48 NTA907HD166-207Q 03/29/2010Assemble Hitch(see Parts Manual page: Hitch)Refer to Figure 85Air Drill Hitched to Tractor(see Operator Manual section:

Assembly 4903/29/2010 166-207QRoute Hoses(see Parts Manual section: Hydraulics)Refer to Figure 87Hydraulic hoses will be routed through the right bulk

50 NTA907HD166-207Q 03/29/2010Hydraulic Hose HookupHigh Pressure Fluid Hazard:Escaping fluid under pressure can have sufficient pressure topenetrate the

Assembly 5103/29/2010 166-207QHydraulic Hose InstallationRefer to Figure 90Hoses are labeled at both ends.Hoses are already hooked up to the valve at

52 NTA907HD166-207Q 03/29/2010Opener Lift Hydraulics(see Parts Manual section: Opener Lift Hydraulics)(see Operator Manual section: Operating Instruct

Assembly 5303/29/2010 166-207QWing Opener Tilt Hydraulics(see Parts Manual section: Wing Opener Tilt Hydrau-lics)(see Operator Manual section: Operati

54 NTA907HD166-207Q 03/29/2010Transport Hook-Wing Fold Hydraulics(see Parts Manual section: Transport Hook and FoldHydraulics)(see Operator Manual sec

Assembly 5503/29/2010 166-207QAuger Hydraulics(see Parts Manual section: Fan and Auger Hydraulics)(see Operator Manual section: Operating Instructions

2 NTA907HD166-207Q 03/29/2010Use A Safety Chain▲ Use a safety chain to help control drawn machinery shouldit separate from tractor draw-bar.▲ Use a ch

56 NTA907HD166-207Q 03/29/2010Auger Latched for Movement(see Operator Manual section: Auger Operations)Latch the auger into its cradles and pin the ar

Assembly 5703/29/2010 166-207QFan Hydraulics(see Parts Manual section: Fan and Auger Hydraulics)(see Operator Manual section: Fan Operation)Refer to F

58 NTA907HD166-207Q 03/29/2010Weight Transfer Hydraulics(see Parts Manual section: Weight Transfer Hydraulics)(see Operator Manual section: Adjusting

Assembly 5903/29/2010 166-207QElectric Harness (Monitor)(see Parts Manual section: Monitor)Refer to Figure 108Locate and install system components as

60 NTA907HD166-207Q 03/29/2010Brake Hookup (Option)Two air drill braking (trailer braking) systems are avail-able:• Dual-line air system with independ

Assembly 6103/29/2010 166-207QParking Brakes(see Parts Manual section: Parking Brakes)(see Operator Manual section: Brake Operation)Refer to Figure 11

62 NTA907HD166-207Q 03/29/2010Air Brakes(see Parts Manual section: Air Brakes)(see Operator Manual section: Brake Operation)Refer to Figure 115Service

Assembly 6303/29/2010 166-207QHydraulic Brakes(see Parts Manual section: Hydraulic Brakes)(see Operator Manual section: Brake Operation)Refer to Figur

64 NTA907HD166-207Q 03/29/2010International Decals(see Parts Manual section: International Decals)Refer to Figure 120Figure 120International Decals294

Important Safety Information 303/29/2010 166-207QPractice Safe Maintenance▲ Understand procedure before doing work. Use propertools and equipment. For

Great Plains Manufacturing, Inc.Corporate Office: P.O. Box 5060Salina, Kansas 67402-5060 USAEOD

4 NTA907HD166-207Q 03/29/2010IntroductionThis 9m No-Till Heavy Duty Air Drill has been designedwith care and built by skilled workers using quality ma

Introduction 503/29/2010 166-207QGetting StartedRefer to Figure 2ForkliftA forklift or overhead hoist is required with 2,950 kg(6,500-pound) capacity.

(12 pages)

(12 pages)

Comments to this Manuals